The presence of copper may go unnoticed, but it is there, used as a resistant, durable, recyclable material with high thermal and electrical conductivity. These are properties that guarantee its validity as an essential raw material for the construction of the civilization that began thousands of years ago.

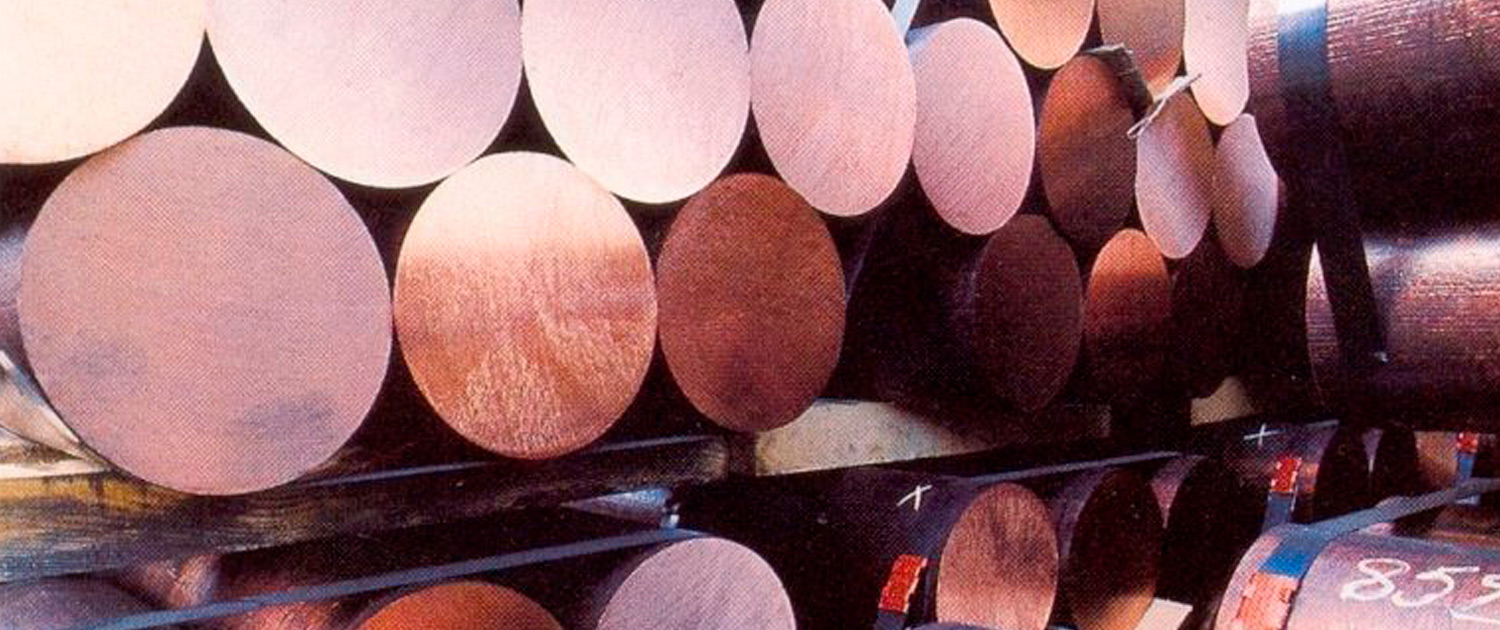

Our TVH® TV-ETP refined copper formats are later transformed into pieces destined to supply the manufacturing industry with products for society’s consumption.

Copper

Copper is key to electricity generation and distribution as it is an excellent conductor of that energy. In the case of telecommunications, it is the most common raw material in the manufacture of telephone cables, and the development of new technologies to increase efficiency in data transmission also positions this material as an important option for the development of broadband connectivity.

Copper may be closer to us than we think, either in pure form or as part of alloys. It appears on coins, kitchen utensils, jewelry, art objects, ornaments, furniture, make-up and paintings, musical instruments, clothing…

In the field of transport, the presence of copper is very important. This material is present in cars, trains, planes, ships, and even space vehicles. It is used in motors, electronic systems and electrical systems.

Some properties of copper, such as the fact that it is a good thermal conductor, strong, resistant to corrosion and non-magnetic, determine its use in alloys intended for the construction of specialized machinery and parts intended for industrial processes.

Types of alloys

Traid Villarroya

NON-FERROUS METALS

TVH® TV-ETP (Cu-ETP)

TVH® TV-ETP (Cu-ETP)

Technical Information TVH® Copper

For more information, we suggest you look in the download area of the top menu, however, we point out the most downloaded files usually in .pdf format.

If you want more information, please contact us

Contact us to request more information about our services.

We are members of the European Plastics Distributors Association (EPDA), The Performance Plastics Association (IAPD) and we actively collaborate with the Technological Institute of Plastics (AIMPLAS).