These materials are Iron-Carbon alloys with high percentages and are called foundries because this is the industrial manufacturing process of them.

The higher percentage of Carbon means that the melting temperature of these is much lower than that of steels and also achieves a greater fluidity of the liquid material, which allows the filling of parts of smaller thicknesses and complicated shapes, that is, they have better collability.

On the other hand, the lower melting temperature allows the metal-mold interaction to be less aggressive and consequently healthier parts can be obtained.

Their low cost, and excellent collability, have led to an extensive development of these alloys in applications such as: engine blocks, piston liners, gears, valve bodies, automotive parts, and many other parts for machinery.

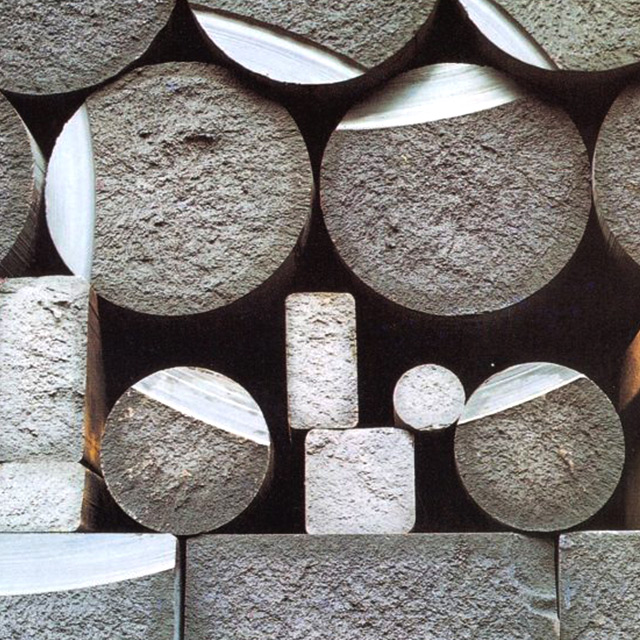

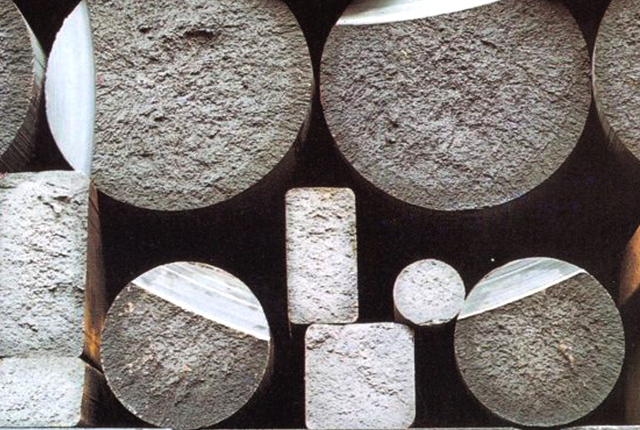

Our TVH® TV25 grey iron bars are one of the most widely used ferrous materials and their name is due to the appearance of their surface when broken. This ferrous alloy generally contains more than 2% carbon and more than 1% silicon, as well as manganese, phosphorus and sulfur.

A distinguishing feature of gray iron is that carbon is generally found as graphite, taking on irregular shapes described as “flakes.” This graphite is what gives the grey colour to the breaking surfaces of parts made of this material.

Characteristics of TVH® GG25 Iron

Traid Villarroya

NON-FERROUS METALS

Good Endurance and Tenacity

Moderate tensile strength and good load-bearing capacity without easily fracturing

High Wear and Abrasion Resistance

Useful for parts that are subject to friction and wear, such as bearings and machinery components

Good Compressive Strength

Suitable for applications where strength under compressive loads is required

Low thermal conductivity

Less suitable for applications that require rapid heat dissipation.

Applications

It is used in various industrial applications, including machinery parts, transmission cases, automotive components, piston liners, engine blocks…

Technical Information TVH® Iron

For more information, we suggest you look in the download area of the top menu, however, we point out the most downloaded files usually in .pdf format.

If you want more information, please contact us

Contact us to request more information about our services.

We are members of the European Plastics Distributors Association (EPDA), The Performance Plastics Association (IAPD) and we actively collaborate with the Technological Institute of Plastics (AIMPLAS).