Immediate stock of bars and plates. Manufacture of tubes, on demand.

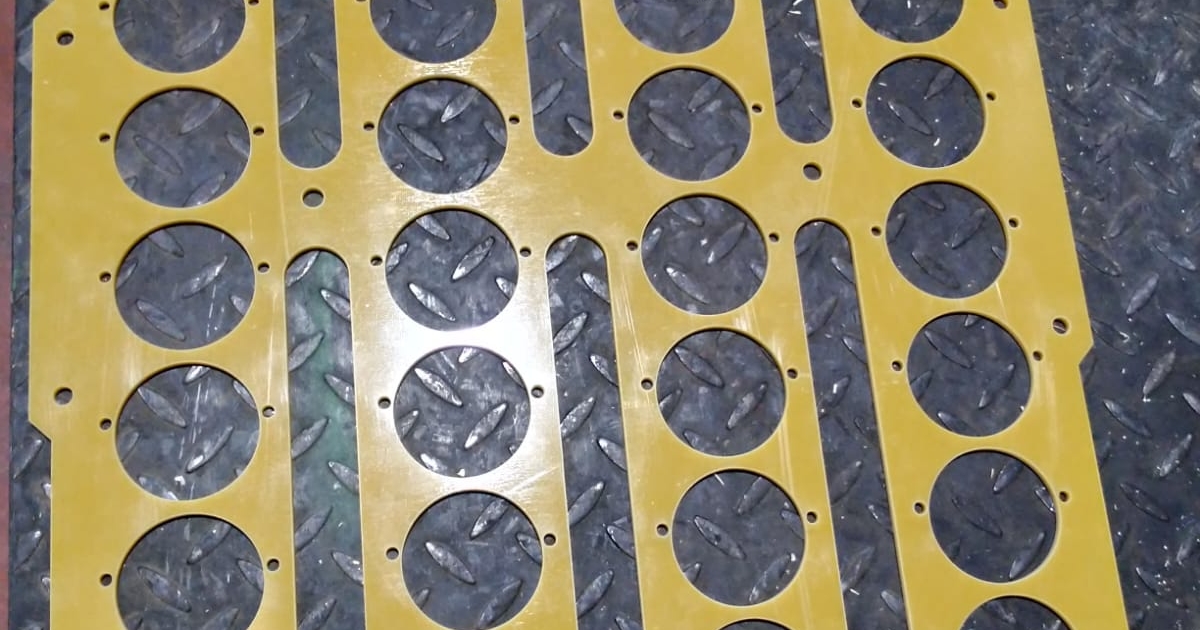

Celotex HGW 2082 has several properties that make it useful in industrial applications, especially in demanding electrical and mechanical environments:

- Electrical insulation: its electrical insulation capacity is excellent, making it an ideal material for electrical devices and insulating parts.

- Shock and vibration resistance: it has a high mechanical resistance, especially to shock and vibration, which makes it suitable for machinery and equipment subjected to dynamic conditions.

- Water resistance: It is resistant to water absorption, which makes it useful in humid environments or in contact with liquids.

- Wear resistance: Due to its composition of phenolic resin and cotton fabric, it withstands prolonged use in parts subject to friction such as bearings, clutch discs and gears.

- Easy machining: This material is easy to machine and mould into different shapes to suit a variety of industrial applications.

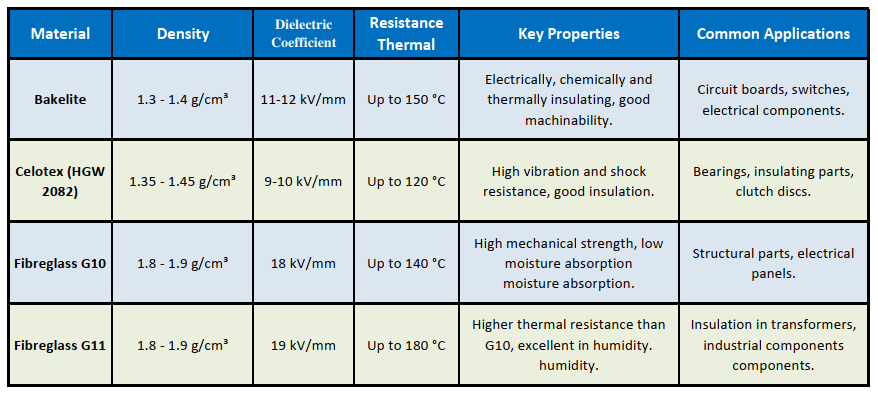

Bakelite (Hp2061)

Bakelite is the first synthetic plastic. It is a thermosetting polymer obtained by the reaction of phenol and formaldehyde. As it is thermosetting, once moulded and hardened, it cannot be remelted.

Main properties:

- Electrical insulation: It does not conduct electricity, making it an excellent material for electrical applications such as plugs and appliance housings.

- Heat resistance: Bakelite withstands high temperatures without warping or melting, making it ideal for components exposed to intense heat.

- Chemical resistance: It is resistant to water, solvents, and other chemicals, making it durable in harsh environments.

- Machinability: Although it is hard and rigid, it can be easily machined, which facilitates its use in the manufacture of industrial products.

- Low cost: Compared to other materials, Bakelite is inexpensive, contributing to its popularity in mass applications for decades.

Immediate stock of plates.

Fibreglass+Epoxy (G10/G11)

Composite materials are widely used for their excellent dielectric and mechanical properties. Both are made of glass fibre layers impregnated with epoxy resin.

Immediate stock of bars and plates.

Common properties:

- High mechanical strength: Both G10 and G11 have excellent tensile and compressive strength, making them ideal for structurally demanding applications.

- Dielectric properties: They offer good electrical insulation, even in wet conditions, making them useful in electrical equipment.

- Low water absorption: Both have very low hydrometric susceptibility, which ensures their dimensional stability in humid environments.

Key differences:

- G10: Mainly used in standard mechanical and electrical applications due to its strength and low cost. See technical data sheet.

Within G10, we find a new variant with improved properties such as GF+Epoxy G10+FR4.

- G11: Has better thermal resistance than G10, withstanding higher temperatures, making it ideal for thermally demanding environments.. See Technical Data Sheet.

Bakelite, Celotex, and glass fibre (G10 and G11) are technical materials used in industry for their excellent insulating properties and mechanical strength. All three materials stand out as excellent electrical insulators, ideal for applications in electronic and electrical equipment; high compressive strength and impact resistance; and resistance to water absorption and various corrosive agents.

These materials maintain their shape and mechanical properties even in difficult conditions such as high temperatures or humid environments.

APPLICATIONS

Materials such as Bakelite, celotex and glass fibre (both G10 and G11) have a wide range of applications in various industries.

Bakelite, known for its moisture resistance and electrical insulation capabilities, is frequently used in the manufacture of electrical components, switches, plugs and in the automotive industry for high-voltage parts.

Celotex is a layered material that excels in applications where mechanical strength and insulation are required, making it ideal for the production of bearings, clutch discs and insulating components in electrical machinery.

G10 and G11 fibreglass, which have excellent mechanical and dielectric properties, are ideal for the manufacture of electrical panels, structures in humid environments and parts that must withstand high temperatures, such as in the aerospace and automotive industries.

These characteristics make these materials essential in the manufacture of parts that require durability and performance under extreme conditions.

Technical Information Celotex / Bakelite/ Fibreglass+Epoxy

For more information, we suggest you look in the download area in the top menu, but we would like to point out the most commonly downloaded files in .pdf format.

If you want more information about laminated materials please contact us.

Contact us to request more information about our services.

We are members of the European Plastics Distributors Association (EPDA), The Performance Plastics Association (IAPD) and we actively collaborate with the Technological Institute of Plastics (AIMPLAS).