Extruded Aluminium is used in cargo transportation, in aircraft fuselages, road vehicles and railways, and for marine applications.

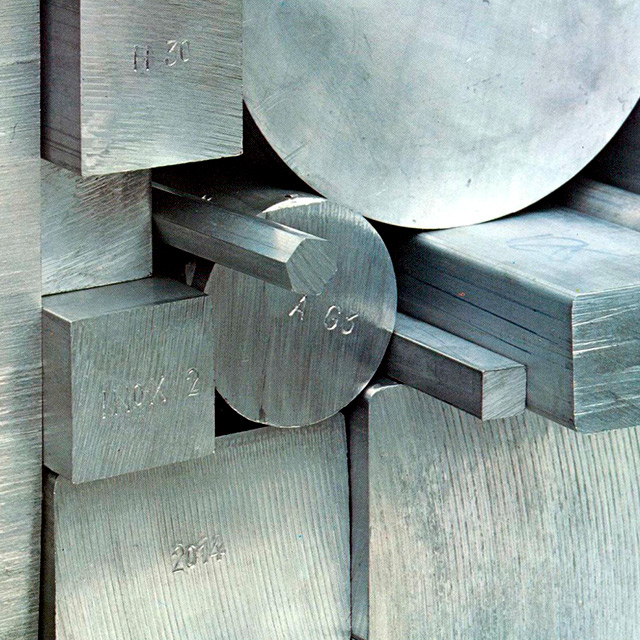

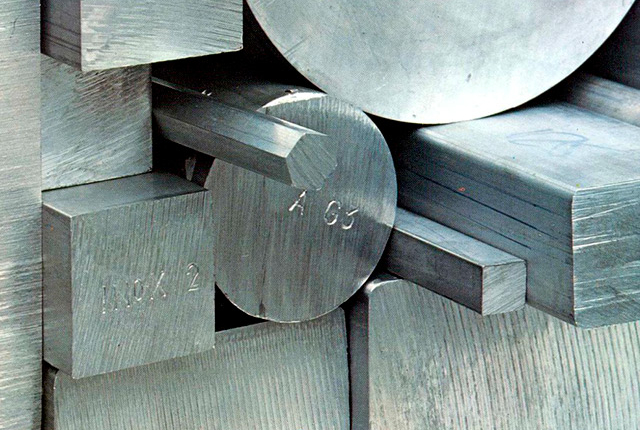

The term “extrusion” is usually applied to both the process and the product obtained when a hot cylindrical Aluminium ingot (called a billet) passes through a properly shaped die (direct extrusion). The resulting profile can be used over long runs, or it can be cut for use in structures, vehicles, or components.

Quality Assurance

The extrusion of our TVH® Aluminium alloys is used as a raw material for machining bars, forging products or cold extrusion products. Although most of the numerous extrusion presses that exist in the world fall within the simple description given, it should be noted that some presses may use rectangular ingots to produce extrusions with a wide cross-section.

Characteristics of TVH® Aluminium

Traid Villarroya

NON-FERROUS METALS

Light

Approximately one-third the weight of steel, ideal material for applications that require weight reduction without compromising strength.

Good mechanical strength

Suitable strength for many industrial applications. Valuable material for various structures and components.

High Thermal and Electrical Conductivity

Suitable for applications where heat dissipation or electricity conduction is required.

Corrosion Resistance

It forms a layer of oxide on its surface that protects it and makes it resistant to weathering and corrosive environments.

High Reflectivity

It reflects light and heat, making it a material used in reflector, mirror, and solar panel applications.

Recyclable

Helps reduce environmental impact and contributes to sustainability

Low Density

Useful in applications where low weight is required such as in the manufacture of aircraft, automobiles and bicycles.

Good Appearance

Glossy, attractive finish, popular in architectural design and consumer product applications.

Alloys

AL2011 + AL2017 + AL2024 + AL2030 + AL6026 + AL6161 + AL6082 + AL7020 + AL7075

Our TVH® Aluminium alloy group has an attractive combination of properties, important both from the point of view of production and use, and has been the subject of a large number of R+D projects in numerous countries. As a result, a set of materials has been obtained, with a resistance between 150 Mpa and 350 Mpa, and all with good hardness and formability.

Technical Information Aluminios TVH®

For more information, we suggest you look in the download area of the top menu, however, we point out the most downloaded files usually in .pdf format.

If you want more information, please contact us

Contact us to request more information about our services.

We are members of the European Plastics Distributors Association (EPDA), The Performance Plastics Association (IAPD) and we actively collaborate with the Technological Institute of Plastics (AIMPLAS).